Initial Prep: was to fully decontaminate the vehicle with a iron remover chemical followed by a wash ,The following step was claying the paint surface to remove embedded surface contaminants .Also during the wash, a wax and grease remover chemical was sprayed on then washed by hand. this ensured that when the vehicle was dried, there wouldn’t be any waxes on the paint . Now that the car was dried it was time to clean the engine bay and get it ready for polishing and coating

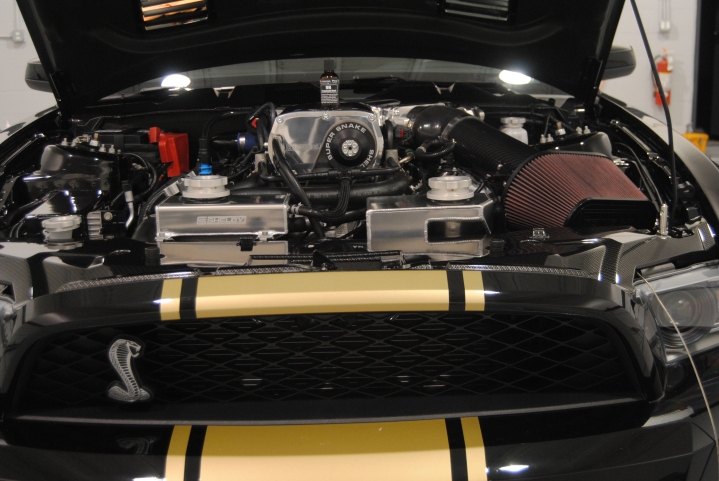

Now that the car was dried it was time to clean the engine bay and get it ready for polishing and coating

Ceramic Pro 9H Was Used to protect the painted and aluminum parts

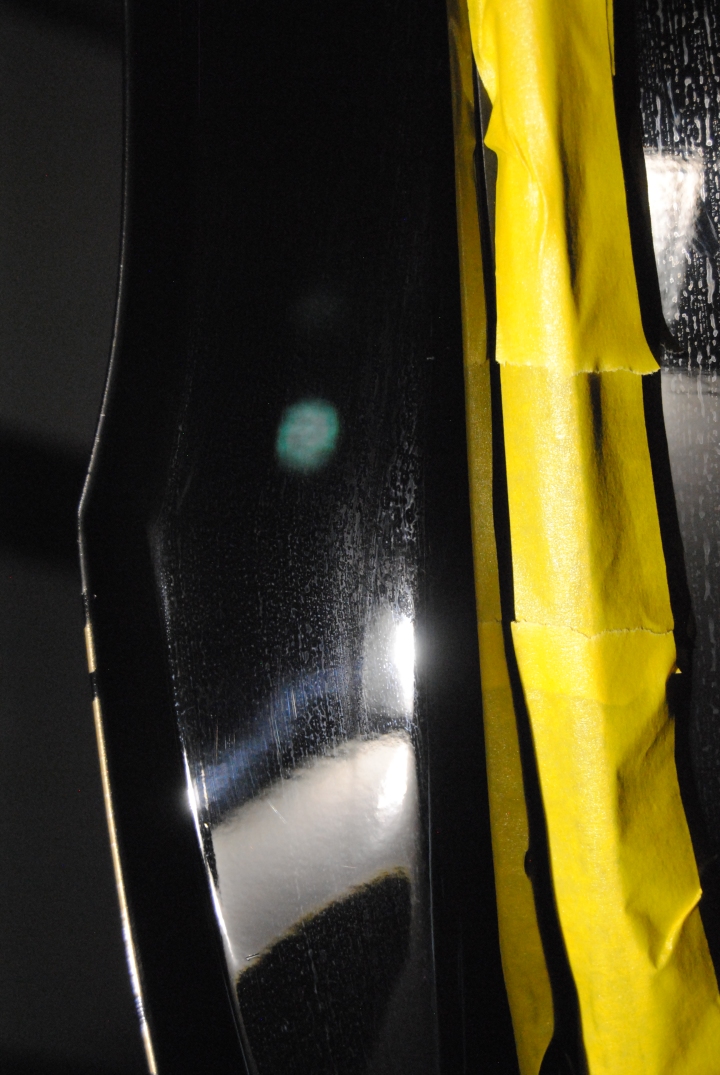

We then moved on to the door jambs this is the condition prior to polishing

We then moved on to the door jambs this is the condition prior to polishing

In order to polish out the overspray,swirls and sand scratches the door striker had to be removed in order to get a uniform look

In order to polish out the overspray,swirls and sand scratches the door striker had to be removed in order to get a uniform look  To protect the interior from polishing dust a plastic sheet was formed to the shape of the door entry .

To protect the interior from polishing dust a plastic sheet was formed to the shape of the door entry . After spending 2 12 hr days perfecting the door jambs it was time to move on to the outside paint. next picture shows a 50/50 of what can be achieved via professional Paint Polishing

After spending 2 12 hr days perfecting the door jambs it was time to move on to the outside paint. next picture shows a 50/50 of what can be achieved via professional Paint Polishing

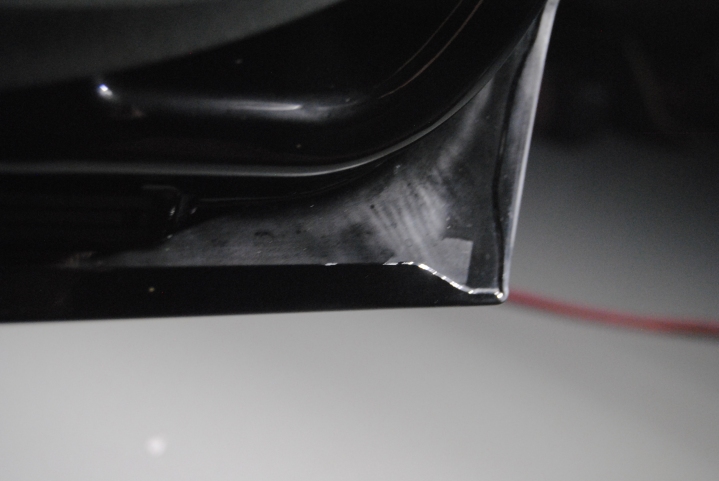

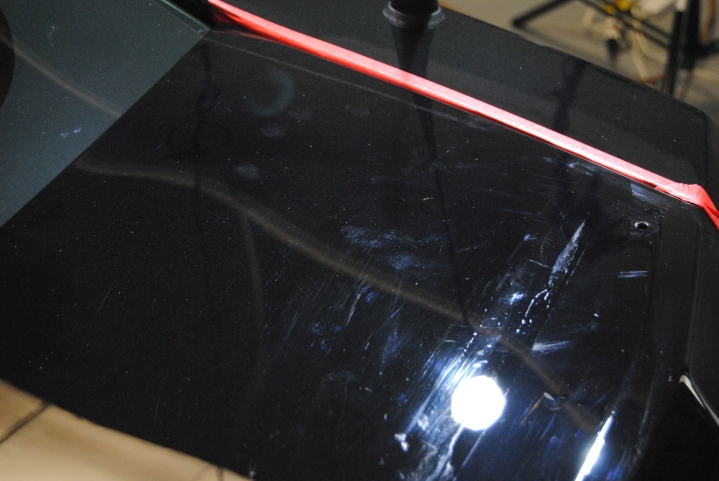

Some panels needed to be wetsanded in order to reduce 80% the orange peel effect thus giving a uniform finish

Some panels needed to be wetsanded in order to reduce 80% the orange peel effect thus giving a uniform finish

After polishing the wetsanded areas i removed the door panels in order to gain access to the door handles and remove hem

After polishing the wetsanded areas i removed the door panels in order to gain access to the door handles and remove hem  Door cup area after removing door handles gave me access in order to remove those ugly fingernail scratches and swirling

Door cup area after removing door handles gave me access in order to remove those ugly fingernail scratches and swirling  Afterwards i moved to the rear and removed the rear wing in order to gain access to the whole trunk lid and correct all

Afterwards i moved to the rear and removed the rear wing in order to gain access to the whole trunk lid and correct all  Overspray on front carbon fiber lip and 50/50 after correction

Overspray on front carbon fiber lip and 50/50 after correction

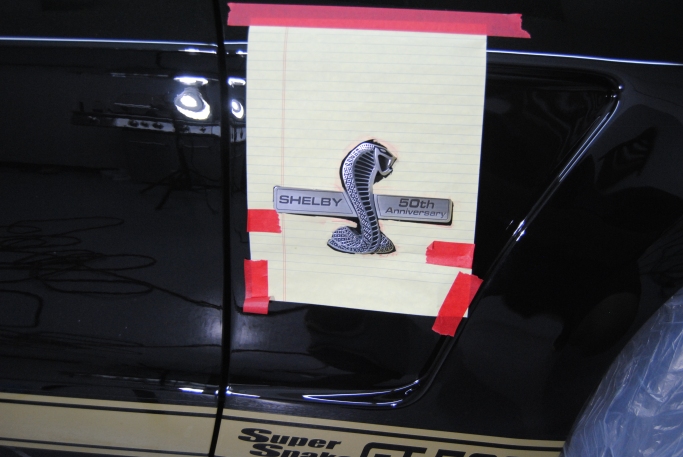

On the front fenders, i custom made a template that gave me the exact factory location to reinstall the Shelby 50th Anniversary and Cobra snake badges. for when i removed them in order to fully correct the area .

On the front fenders, i custom made a template that gave me the exact factory location to reinstall the Shelby 50th Anniversary and Cobra snake badges. for when i removed them in order to fully correct the area .

Next up the wheels were removed, fully cleaned and coated with Ceramic Pro 9H. The wheel on the left is coated and the wheel to the right is in its factory dry sheen. the tires were also cleaned and coated with a tire coating .to eliminate the need to use greasy dressings that sling or stain the car cover

Next up the wheels were removed, fully cleaned and coated with Ceramic Pro 9H. The wheel on the left is coated and the wheel to the right is in its factory dry sheen. the tires were also cleaned and coated with a tire coating .to eliminate the need to use greasy dressings that sling or stain the car cover

While the wheels were removed i then took the time to address the suspension,brake calipers and wheel wells in order to get them ready for the application of nano ceramic protection,Whether by cleaning or polishing. the next pictures show the condition the rear suspension arm and brake calipers were before polishing

Next up the interior was partially disassembled in order to clean and protect every square inch with Ceramic Pro leather and textile coatings.

Next up the interior was partially disassembled in order to clean and protect every square inch with Ceramic Pro leather and textile coatings.

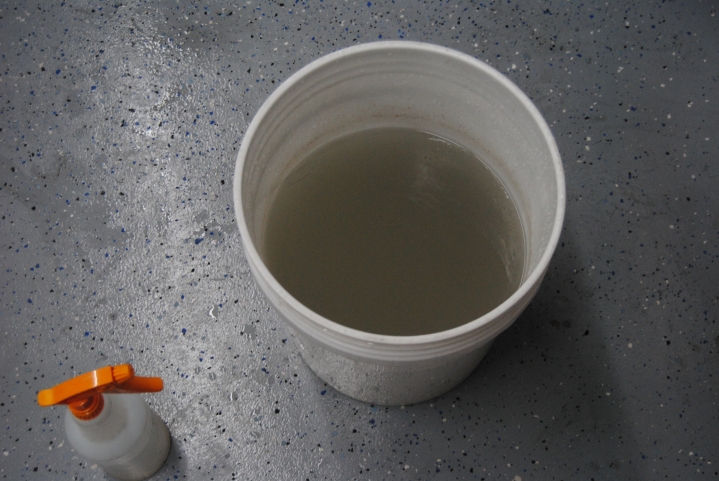

The dirt removed from the interior

The dirt removed from the interior

Final Thoughts: Client mentioned prior to the reconditioning, That the car was “going to be sent to Barret Jackson Auctions in Scottsdale AZ”. Due to him expecting the car to come out “ok” (client has had a unsatisfactory experience with the paint finish of the vehicle ever since it was delivered from the shelby factory) As soon as the vehicle was completed the client was very happy and decided to keep the car in his collection .